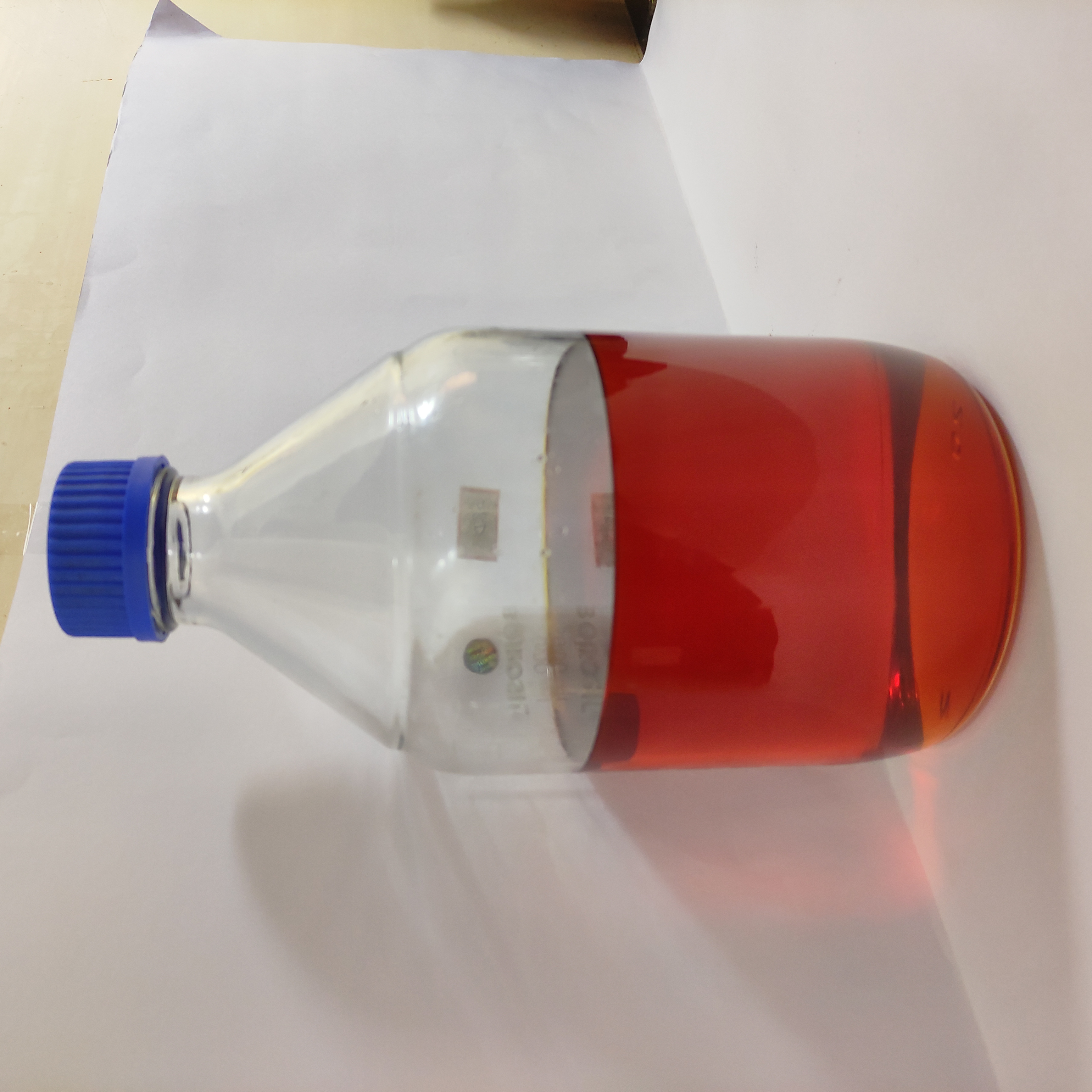

Desilked dried silkworm pupal waste was processed to recover its lipid content as biodiesel. The produced product, i.e., silkworm pupae biodiesel was checked for its physicochemical properties and was found to be of adequate quality for use in diesel engi

USP: The product, i.e., pupal biodiesel is an eco-friendly alternative green fuel, that is obtained from the waste of silk reeling units, contributing towards a circular economy. The catalyst for the production of this biodiesel is also synthesized from a part of this waste. This brings down the cost of production, as feedstock accounts for over 75 of biodiesel production. The product is a cheaper and eco-friendly blend to be used in diesel engines.

- Innovator's Name

- Product/Technology Description

Coimbatore Institute of Technology

- Product Name: Desilked dried silkworm pupal waste was processed to recover its lipid content as biodiesel. The produced product, i.e., silkworm pupae biodiesel was checked for its physicochemical properties and was found to be of adequate quality for use in diesel engi

- Product Title: The silkworm pupae waste generated from silk reeling units was found to have approximately 40 lipids, 54 proteins, and essential minerals in trace quantities. This lipid in the waste was transesterified with an acid catalyst resulting in an approximate 90 yield of biodiesel. This product was characterized using GCMS, FTIR, and 1HNMR spectroscopy. These studies have indicated the presence of good-quality biodiesel. The physicochemical properties of the produced biodiesel were tested according to standard testing methods and were found to be satisfactory. The produced biodiesel was compared with a commercial biodiesel for its properties, and was found to be superior. The energy value of the silkworm pupae biodiesel showed over 10 increase than commercial biodiesel. The exoskeleton of the pupae was converted into a mineral oxide catalyst for transesterification reaction, thus reducing the solid waste generated. This catalyst was more efficient and ecofriendly when compared to that of the acid catalyst. Also, the emission and performance characteristics of the produced biodiesel and biodiesel blends were analysed. It was concluded that this biodiesel is very effective and clean at higher loading rates. The solid residue generated after producing biodiesel was characterised and was found to have nutritional value suitable to be used as a biofertilizer. This renders a zero solid waste management plan for the sericulture industry.

- Description:

- Unique Selling Point: The product, i.e., pupal biodiesel is an eco-friendly alternative green fuel, that is obtained from the waste of silk reeling units, contributing towards a circular economy. The catalyst for the production of this biodiesel is also synthesized from a part of this waste. This brings down the cost of production, as feedstock accounts for over 75 of biodiesel production. The product is a cheaper and eco-friendly blend to be used in diesel engines.