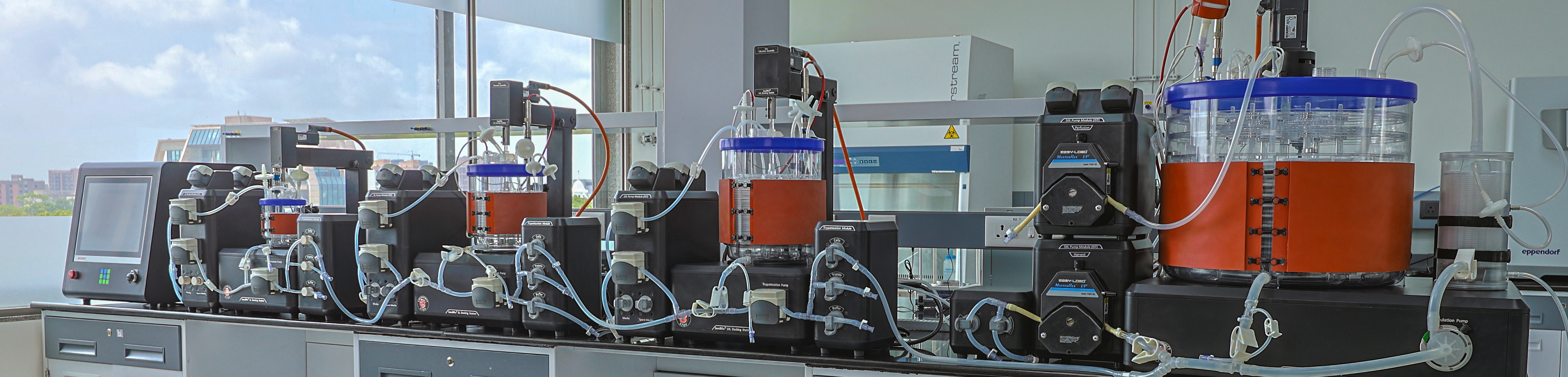

Dynamic-Bed Bioreactor system

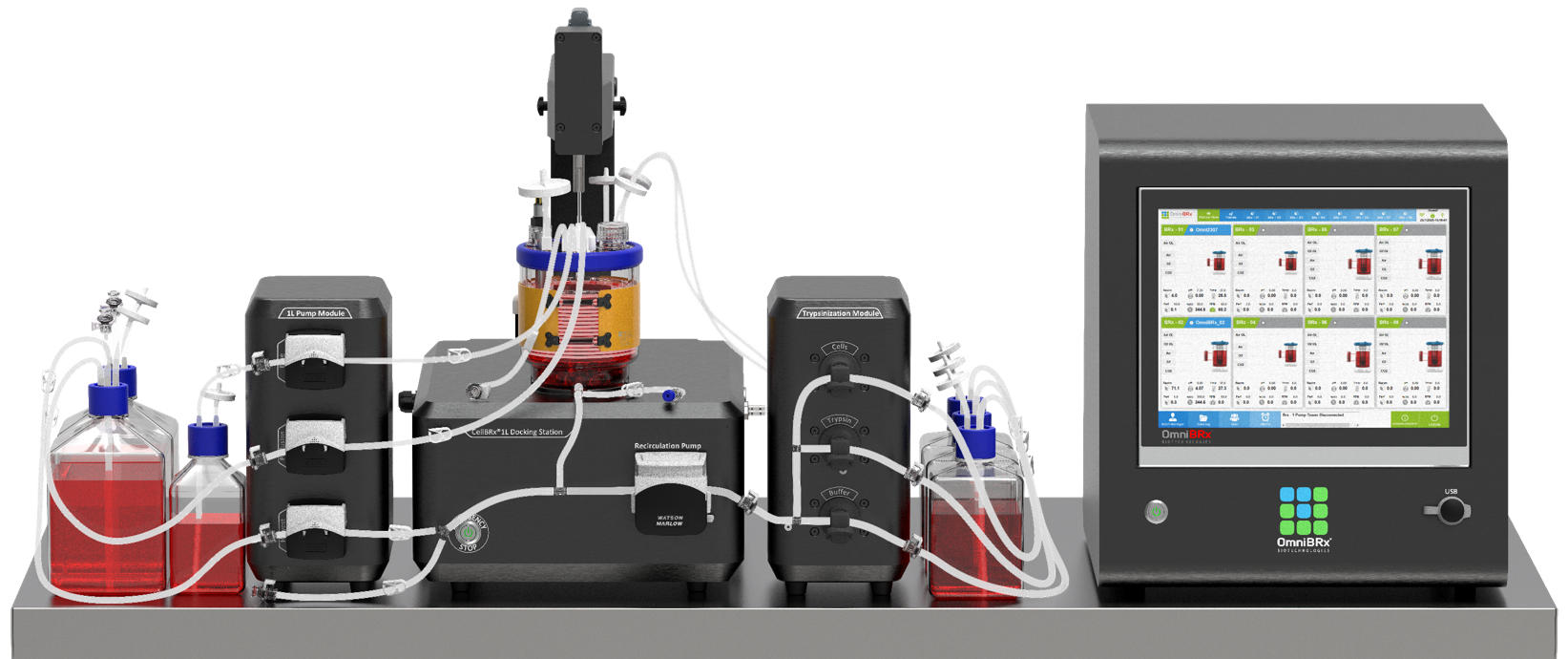

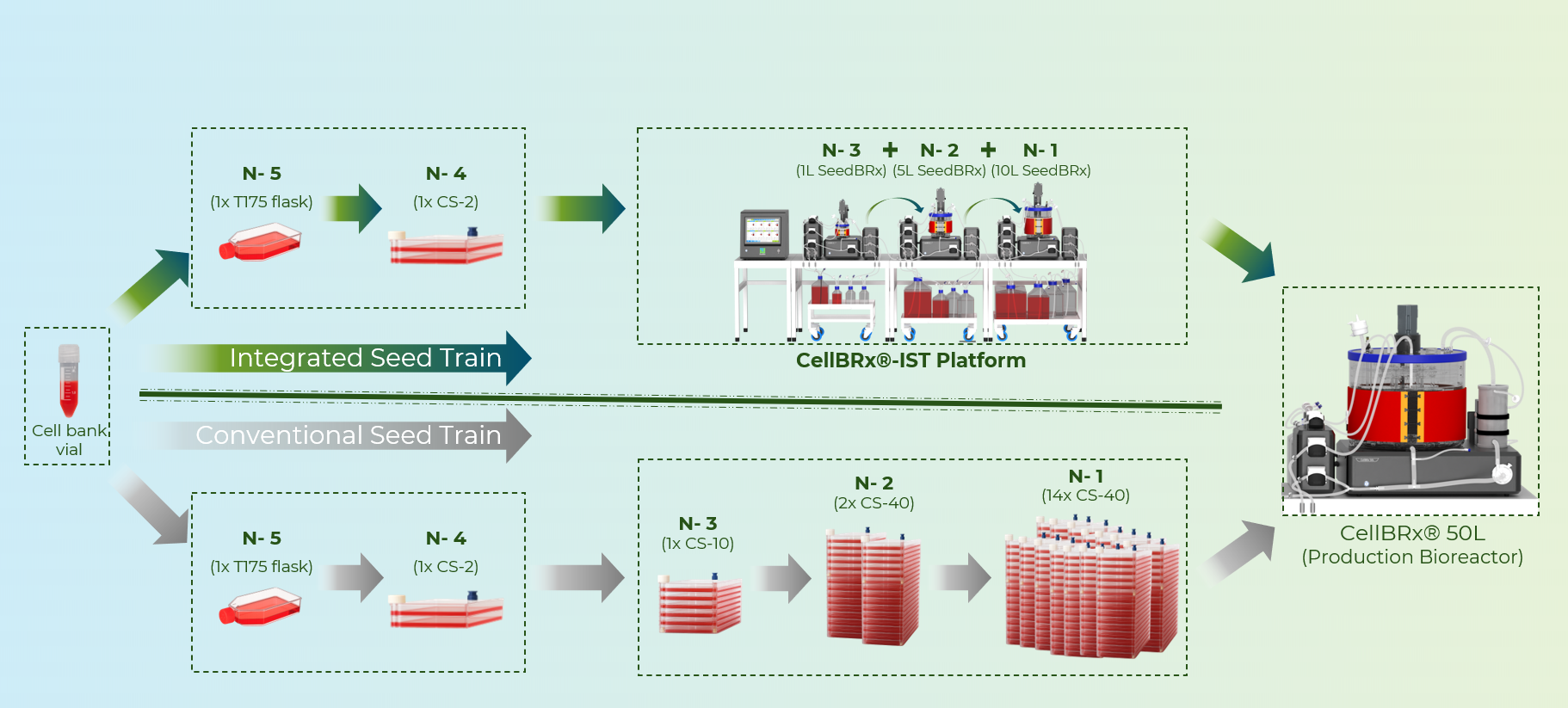

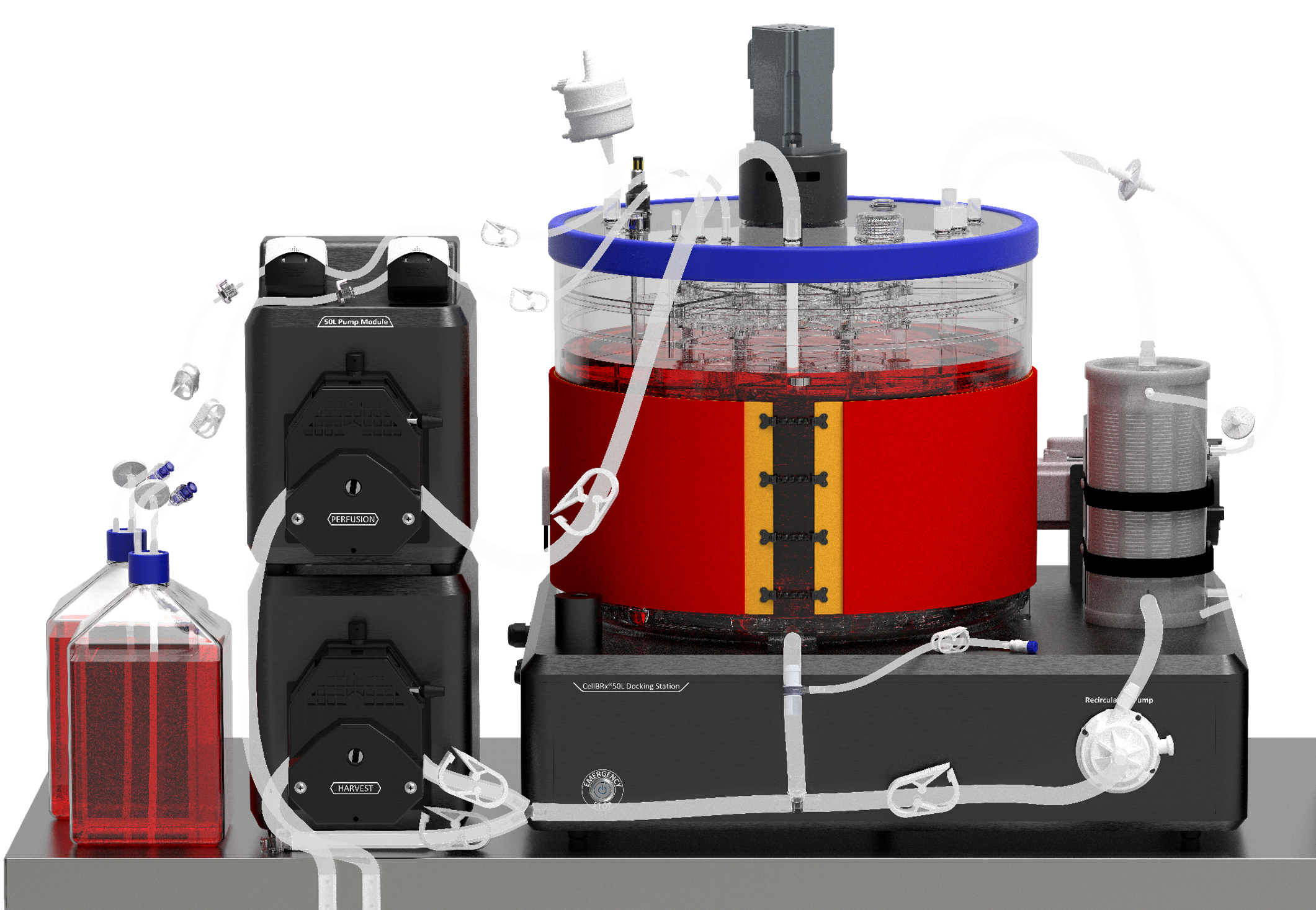

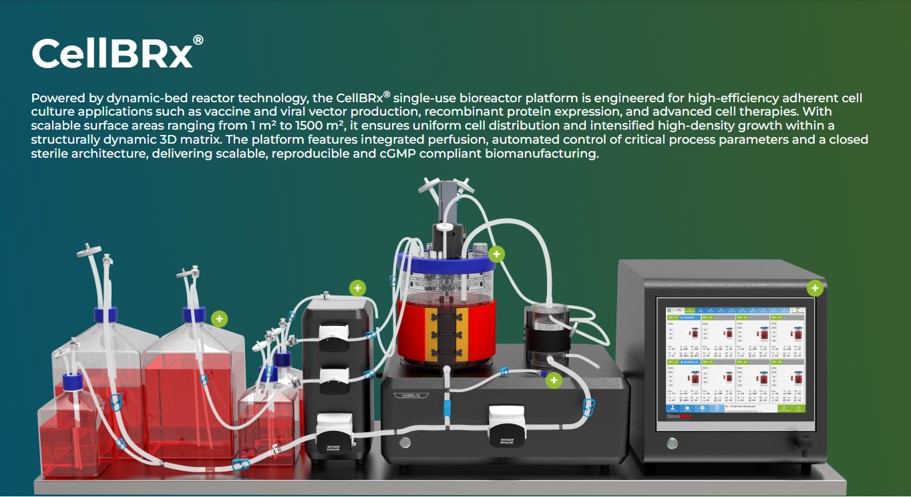

The CellBRx® 5L bioreactor systems are engineered to facilitate pilot-scale experimentation and intermediate-scale commercial production by providing controlled and scalable culture conditions. These systems offer surface area configurations of 10 m², 25 m², and 40 m², with the 40 m² variant corresponding to approximately 63 units of Cell Factories-10 CF-10 or 470 units of roller bottles each 850 cm² . Functioning as a mid-scale stirred bioreactor, the CellBRx® 5L SUB is widely utilized for bioprocess scale-up studies and the optimization of critical physical parameters. These include agitation rate, aeration rate, temperature, pH, and dissolved oxygen concentration, all of which are crucial for maintaining optimal cell growth and productivity.

USP: With our proprietary and innovative DBR technology these existing problems like scalability, efficiency and affordability will be well addressed. DBR technology offers very large surface area for adherent cell growth in small culture volume and the innovative design offers effective mixing to ensure homogeneous nourishment and mass transfer while scaling up. The technology offers linear scalability from 1L to 200L with automated bioprocessing convenience using integrated controllers and require small facility footprint very compact design.

- Innovator's Name

- Product/Technology Description

At OmniBRx, innovation drives every breakthrough. We pioneer novel bioprocessing solutions by merging cutting-edge engineering with deep domain expertise.

- Product Name: Dynamic-Bed Bioreactor system

- Product Title: 5L CellBRx Bioreactor system

- Description: The CellBRx® 5L bioreactor systems are engineered to facilitate pilot-scale experimentation and intermediate-scale commercial production by providing controlled and scalable culture conditions. These systems offer surface area configurations of 10 m², 25 m², and 40 m², with the 40 m² variant corresponding to approximately 63 units of Cell Factories-10 CF-10 or 470 units of roller bottles each 850 cm² . Functioning as a mid-scale stirred bioreactor, the CellBRx® 5L SUB is widely utilized for bioprocess scale-up studies and the optimization of critical physical parameters. These include agitation rate, aeration rate, temperature, pH, and dissolved oxygen concentration, all of which are crucial for maintaining optimal cell growth and productivity.

- Unique Selling Point: With our proprietary and innovative DBR technology these existing problems like scalability, efficiency and affordability will be well addressed. DBR technology offers very large surface area for adherent cell growth in small culture volume and the innovative design offers effective mixing to ensure homogeneous nourishment and mass transfer while scaling up. The technology offers linear scalability from 1L to 200L with automated bioprocessing convenience using integrated controllers and require small facility footprint very compact design.