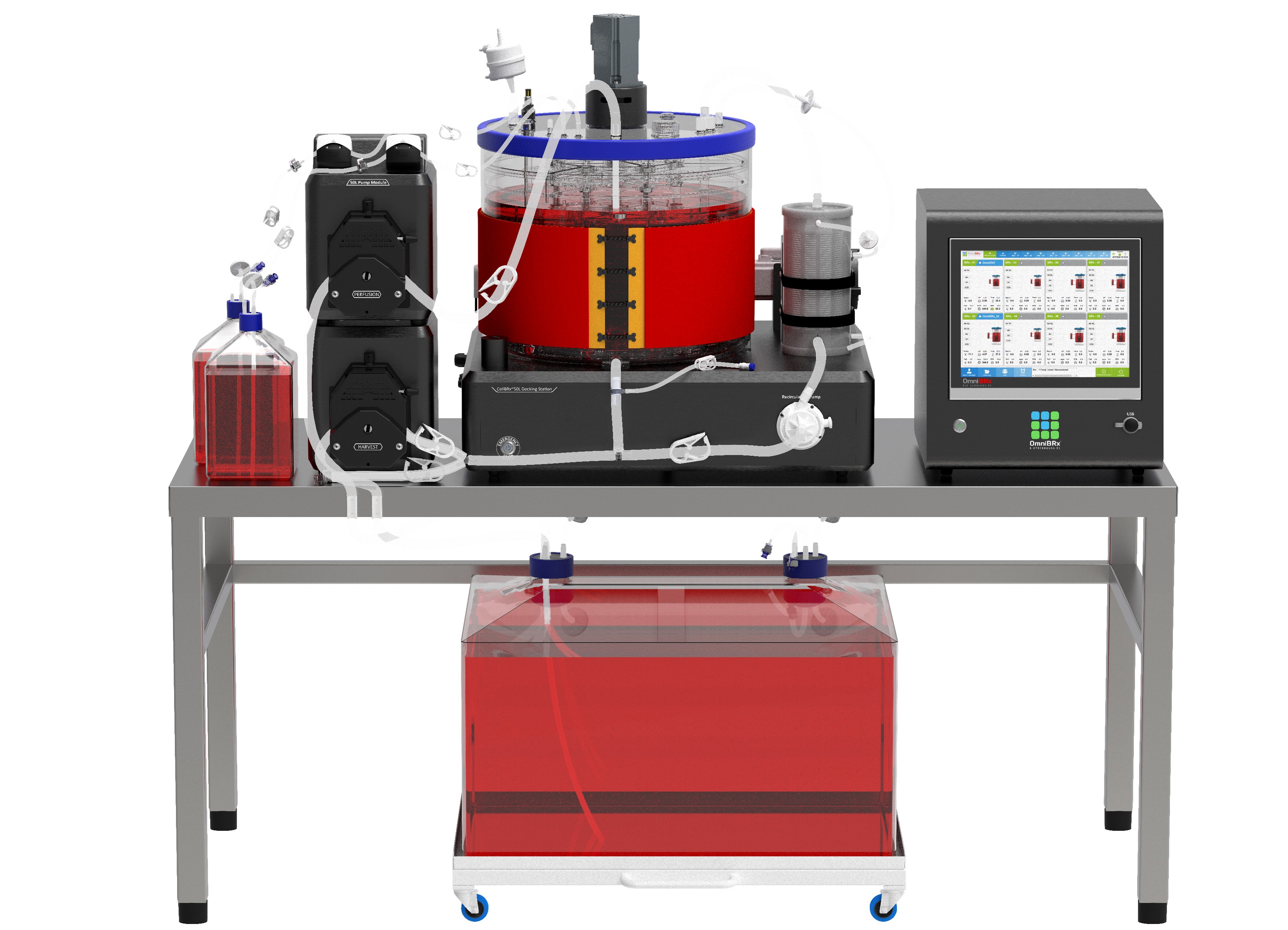

Dynamic-Bed Bioreactor system

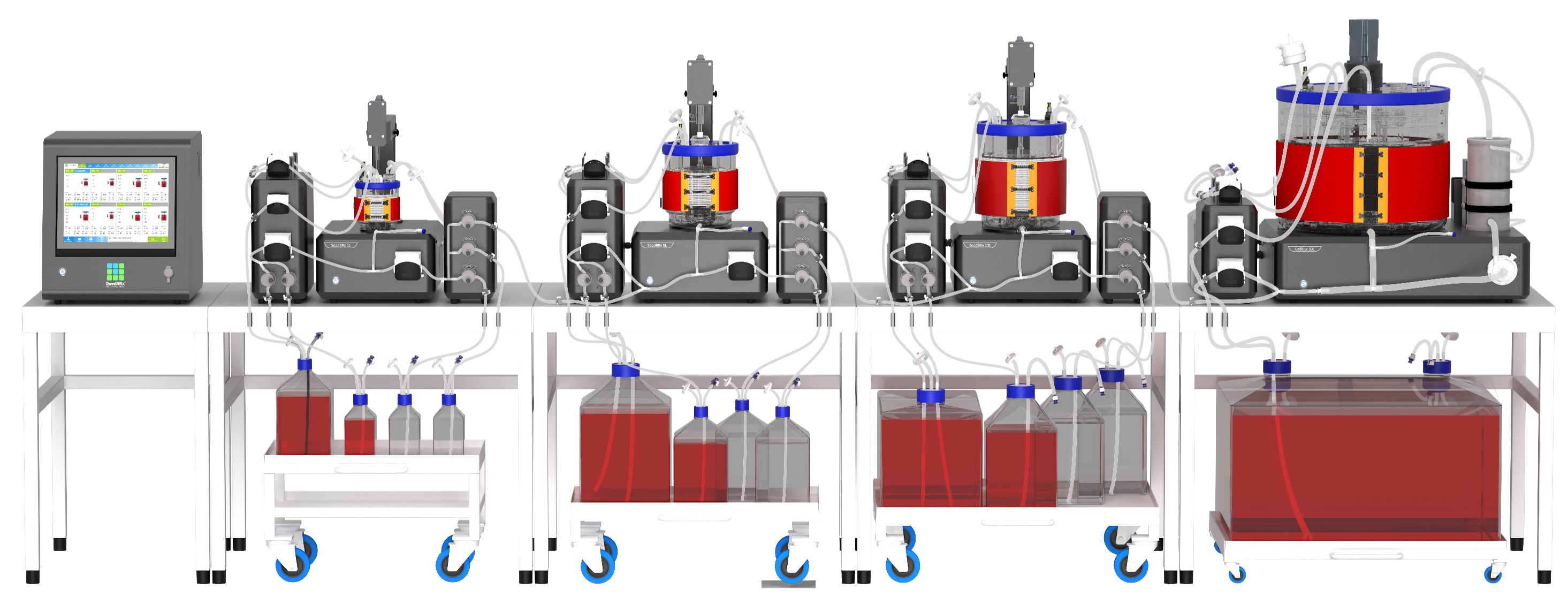

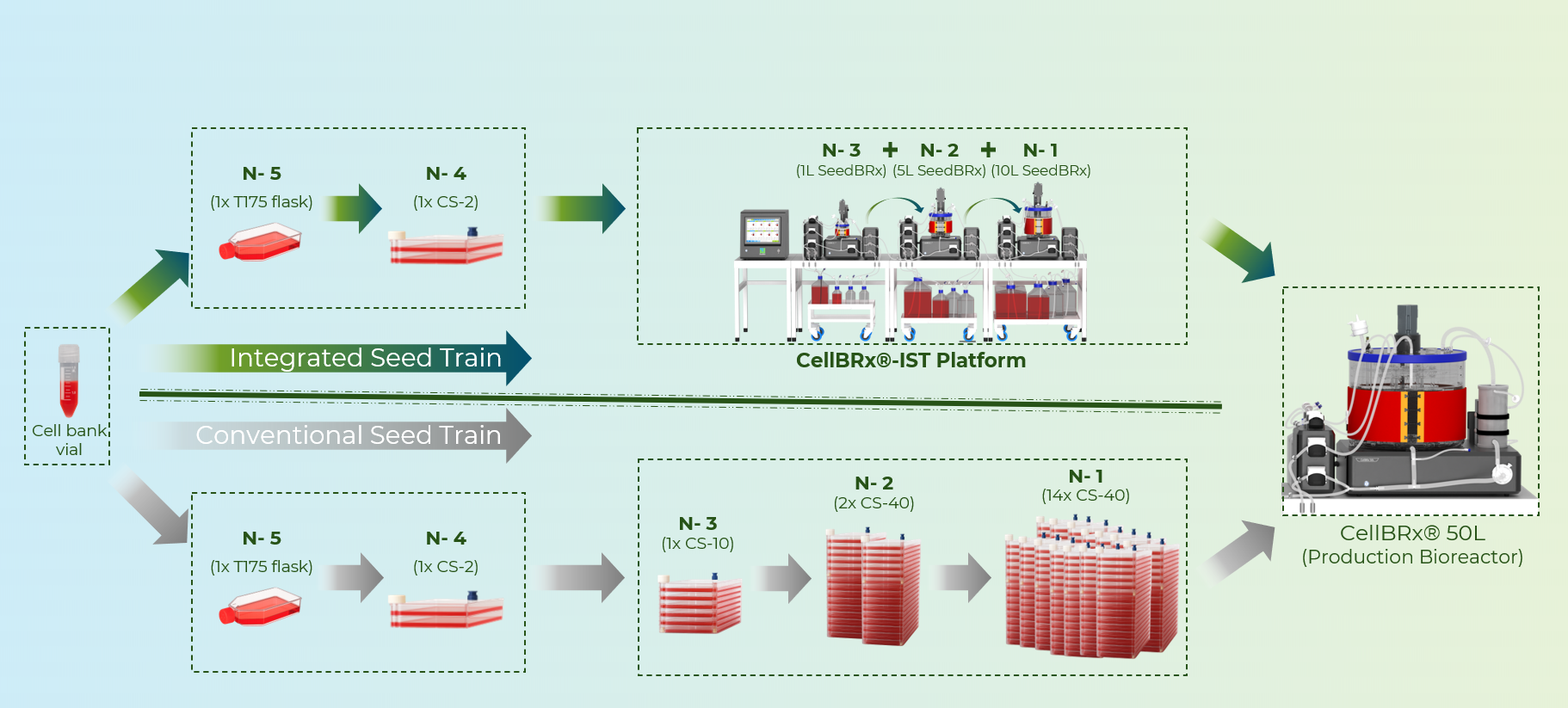

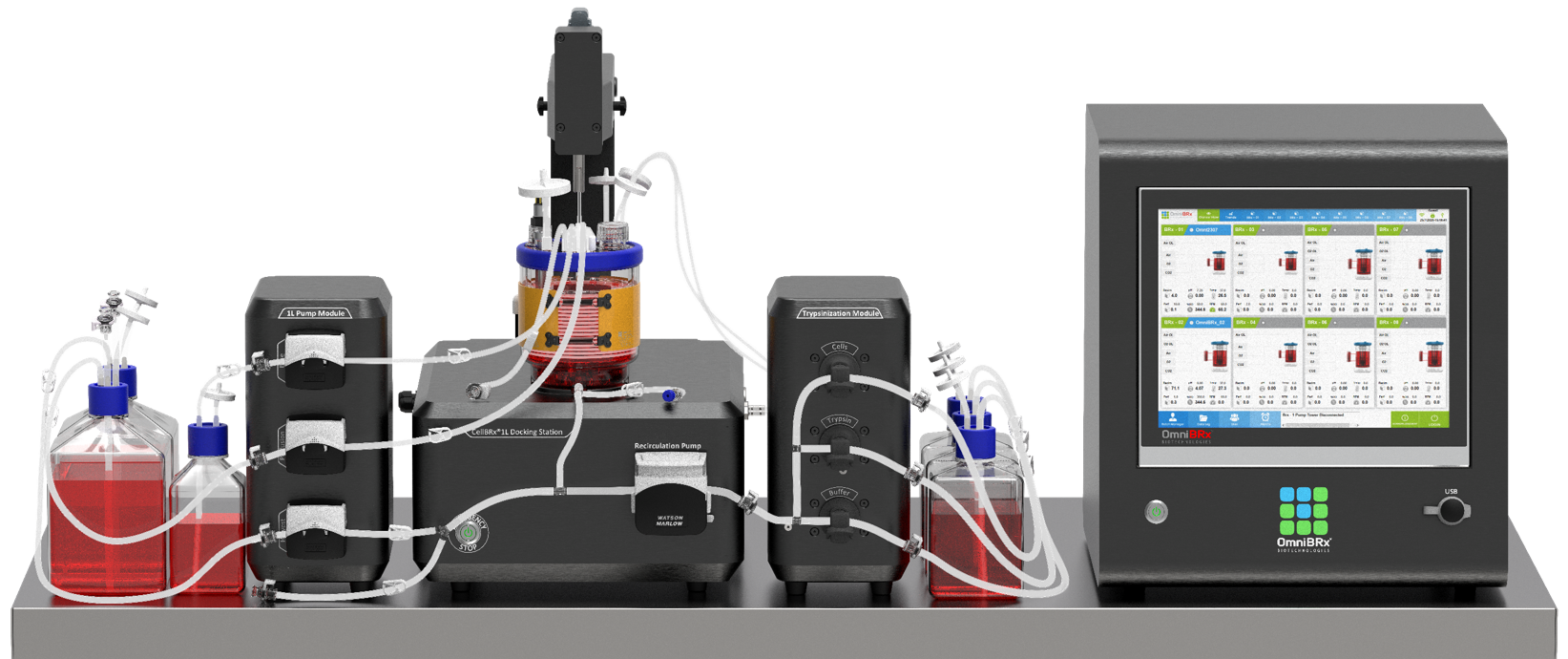

USP: Scalability and Process Flexibility: The modular design of the CellBRx® platform supports linear scalability from 1L to 200L, accommodating surface areas from 1 m² to 1500 m². This seamless transition from small-scale research to commercial-scale production ensures reproducibility and reliability throughout the bioprocessing workflow. Integrated Perfusion for Process Intensification: Automated, precisely controlled media exchange protocols optimize cell growth conditions, leading to high cell densities and enhanced product yields. The integration of advanced single-use bioreactor technology streamlines process workflows, significantly reducing development timelines and expediting market entry for biopharmaceutical products. Compact, Efficient, and Smart Control: With a space-saving footprint, CellBRx® boosts volumetric productivity while reducing facility and operating costs. Delivered pre-assembled with pre-calibrated sensors, it offers plug-and-play setup and precise control over key parameters, pH, DO, temperature, and perfusion, for reliable, high-quality output. The Dynamic-Bed Reactor DBR technology: CellBRx® utilizes proprietary DBR technology optimized for high-density adherent cell growth. Its compact, low-shear and dynamic 3D matrix maximizes surface area, ensuring efficient nutrient and gas exchange. With scalable surface areas from 1 m² to 1500 m², it supports consistent performance from R&D to cGMP production.

- Innovator's Name

- Product/Technology Description

OmniBrx Biotechnologies Pvt Ltd.

- Product Name: Dynamic-Bed Bioreactor system

- Product Title: CellBRx Bioreactor systems

- Description: Powered by dynamic-bed reactor technology, the CellBRx® single-use bioreactor platform is engineered for high-efficiency adherent cell culture applications such as vaccine and viral vector production, recombinant protein expression, and advanced cell therapies. With scalable surface areas ranging from 1 m² to 1500 m², it ensures uniform cell distribution and intensified high-density growth within a structurally dynamic 3D matrix. The platform features integrated perfusion, automated control of critical process parameters and a closed sterile architecture, delivering scalable, reproducible and cGMP compliant biomanufacturing. Key Features & Advantages: Revolutionizing Adherent Cell Culture with DBR Technology The Dynamic-Bed Reactor DBR technology: CellBRx® utilizes proprietary DBR technology optimized for high-density adherent cell growth. Its compact, low-shear and dynamic 3D matrix maximizes surface area, ensuring efficient nutrient and gas exchange. With scalable surface areas from 1 m² to 1500 m², it supports consistent performance from R&D to cGMP production. Regulatory Compliance and Quality Assurance: Manufactured in ISO Class 8 cleanrooms, CellBRx® SUBs meet global quality standards including, USP 87 , 88 , 85 , 71 , 788 , ISO 11137, BPOG extractables, and are ADCF compliant. The process control SCADA software comply with 21 CFR Part 11 and GAMP 5 for robust data integrity and regulatory compliance. Scalability and Process Flexibility: The modular design of the CellBRx® platform supports linear scalability from 1L to 200L, accommodating surface areas from 1 m² to 1500 m². This seamless transition from small-scale research to commercial-scale production ensures reproducibility and reliability throughout the bioprocessing workflow. Integrated Perfusion for Process Intensification: Automated, precisely controlled media exchange protocols optimize cell growth conditions, leading to high cell densities and enhanced product yields. The integration of advanced single-use bioreactor technology streamlines process workflows, significantly reducing development timelines and expediting market entry for biopharmaceutical products. Compact, Efficient, and Smart Control: With a space-saving footprint, CellBRx® boosts volumetric productivity while reducing facility and operating costs. Delivered pre-assembled with pre-calibrated sensors, it offers plug-and-play setup and precise control over key parameters—pH, DO, temperature, and perfusion—for reliable, high-quality output.

- Unique Selling Point: Scalability and Process Flexibility: The modular design of the CellBRx® platform supports linear scalability from 1L to 200L, accommodating surface areas from 1 m² to 1500 m². This seamless transition from small-scale research to commercial-scale production ensures reproducibility and reliability throughout the bioprocessing workflow. Integrated Perfusion for Process Intensification: Automated, precisely controlled media exchange protocols optimize cell growth conditions, leading to high cell densities and enhanced product yields. The integration of advanced single-use bioreactor technology streamlines process workflows, significantly reducing development timelines and expediting market entry for biopharmaceutical products. Compact, Efficient, and Smart Control: With a space-saving footprint, CellBRx® boosts volumetric productivity while reducing facility and operating costs. Delivered pre-assembled with pre-calibrated sensors, it offers plug-and-play setup and precise control over key parameters, pH, DO, temperature, and perfusion, for reliable, high-quality output. The Dynamic-Bed Reactor DBR technology: CellBRx® utilizes proprietary DBR technology optimized for high-density adherent cell growth. Its compact, low-shear and dynamic 3D matrix maximizes surface area, ensuring efficient nutrient and gas exchange. With scalable surface areas from 1 m² to 1500 m², it supports consistent performance from R&D to cGMP production.